Materials

While modern blacksmithing is often rooted in the strength of mild steel, my practice is driven by a deep fascination with how raw materials can be transformed into expressive art. Beyond the structural power of steel, I embrace the heritage of wrought iron for delicate restoration work, breathing new life into historical craftsmanship.

To me, a design truly comes alive when it becomes a symphony of textures and tones. I love to challenge the boundaries of metal by weaving in elements that dance with light and shadow—whether it’s the warmth of copper and brass, the sleek brilliance of stainless steel, or the timeless weight of bronze. By incorporating the organic grain of wood, the grounded presence of stone, or the vibrant, fractured beauty of glass and mosaic tiling, I create pieces that offer more than just function. They are tactile experiences, rich with contrast and designed to captivate the eye from every angle.

Techniques

For three millennia, the blacksmith has stood at the crossroads of art and industry, wielding fire and hammer to shape the very course of human civilisation. To step into a forge is to join a lineage of makers that stretches back 3,000 years—a legacy of alchemists who discovered that within the roar of the hearth, stubborn iron yields its soul.

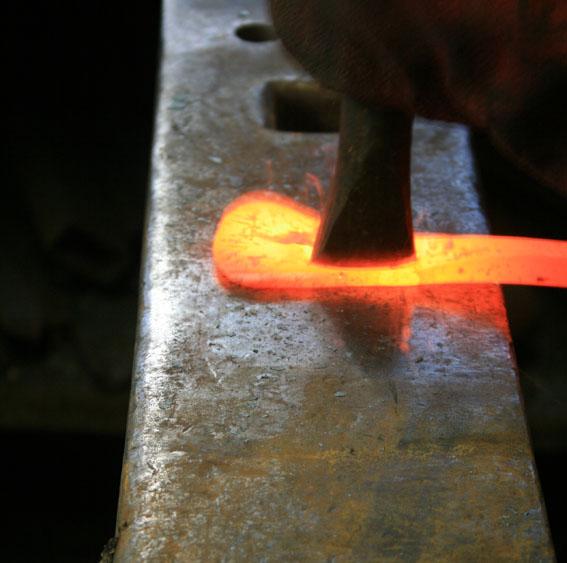

When the metal glows at a white-hot heat, it enters a state of grace, becoming as malleable as clay. In this fleeting window of opportunity, the smith employs an ancient vocabulary of movement to transform raw bars into intricate masterpieces:

The Language of the Forge

The Foundation of Form: Through forging, the smith commands the metal to move—drawing it down to stretch it thin, upsetting it to thicken its mass, or spreading it to create broad, sweeping surfaces.

The Architecture of Detail: Precision emerges through splitting and punching, while twisting and bending introduce the flowing curves and rhythmic patterns that define ornamental ironwork.

The Mastery of Strength: Beyond shape lies the hidden science of heat treating. By normalising, annealing, and tempering, the smith "tunes" the metal, balancing surgical hardness with resilient flexibility.

The Art of Connection: Elements are bound together not just by utility, but by craft—using fire welding to fuse two pieces into one, or employing collars, rivets, and the timeless mortise and tenon joint.

This mastery over the elements grants a rare kind of creative sovereignty. Between the heat of the fire and the strike of the hammer, the iron becomes a fluid medium. In this space, the blacksmith is no longer bound by the rigid nature of the material, but is free to realise the wildest visions of the imagination and the specific desires of the client, turning cold ore into a warm, living expression of history.

Materials

Techniques used while making a bird head from 12mm square mild steel

Upsetting - squashing down the bar to add more material for the feathers

Spreading - moving the material [that has been upset] to the sides with the cross pein

Marking patterns with the chisel and O punch

Bending the bar in preparation for fire welding the beak

Fire welding the fold together by heating the bar close to its melting point and tapping it together so it joins into one piece - amazing metal!

The bird after fire welding and marking the eye with the O punch

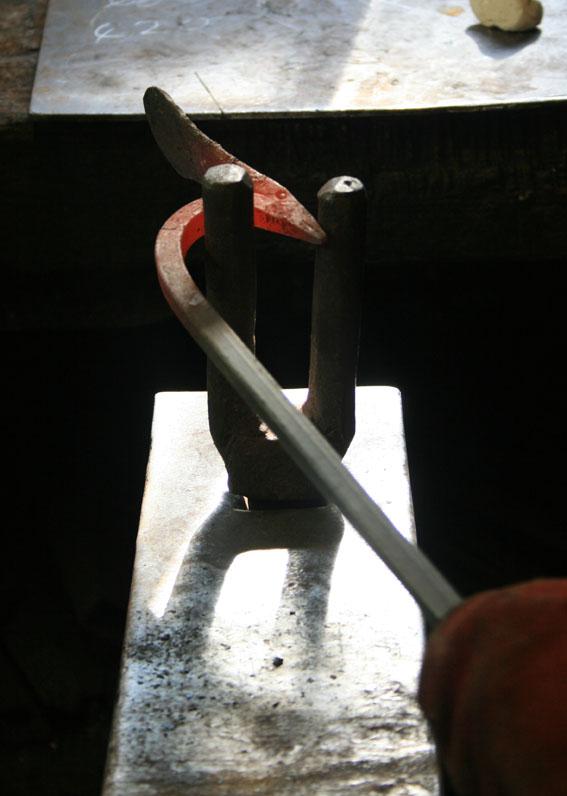

Bending the head round over the edge of the anvil and using the hardie wrench/pegs

Cutting on my curved cut-off hardie tool

Spreading and shaping the end once it has been cut off

Punching the holes in by hitting an impression on one side, then turning it over to pop a hole through.

Other techniques

Twisting flat bar. Simply turn with the wrench, and the corners or grooves create the pattern

Twisting square bar

Drawing down - a forging technique [along with spreading and upsetting], where I am changing the section of the metal between the hammer and anvil

Splitting the metal with a chisel

Drawing down/Forging the split into a point/taper, then bending over the bic

Dishing the copper on the swage block. The swage block is handy for dishing as I can use all the hollow areas to hit the sheet down into. It also accepts my tin smithing tools so I can planish it [hit the bumps down and smooth it off]

This bit of sheet metal has been fullered, dished and bent

That's A Wrap!